-

- Contact Us

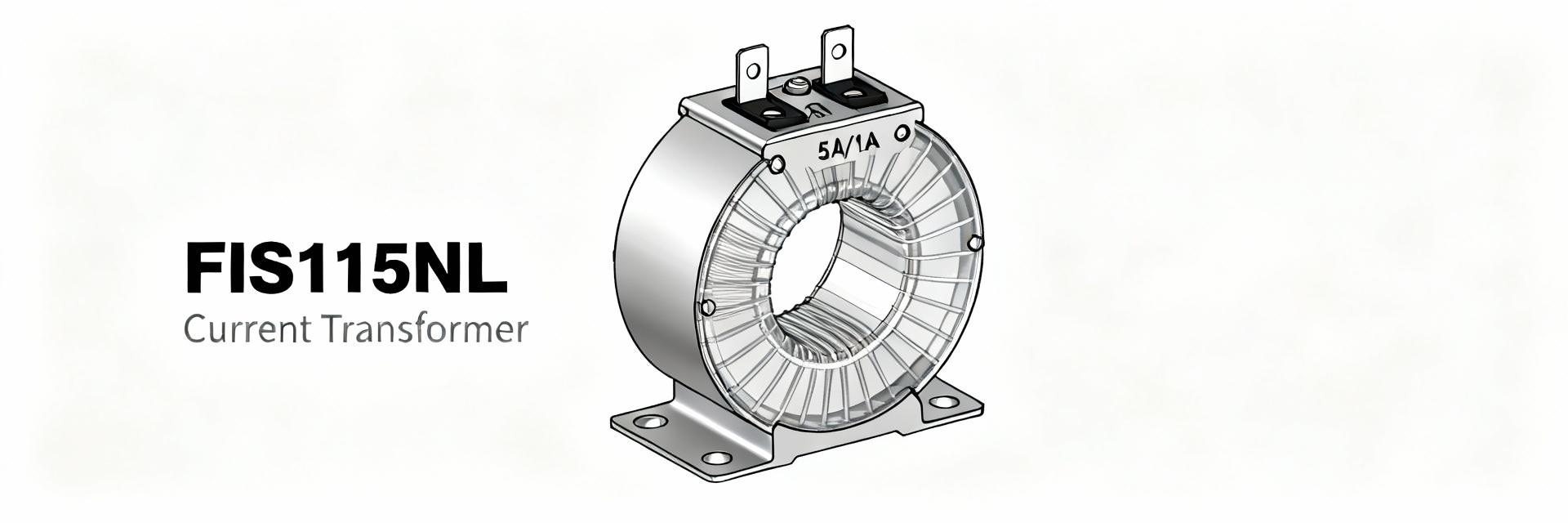

FIS115NL current sense transformer: Complete Specs & Limits

The FIS115NL is a compact 1:100 current sense transformer whose headline electrical figures set expectations for SMPS feedback and protection: approximately 1:100 turns ratio, ~18 mH magnetizing inductance, ~2 Ω secondary DC resistance, up to 500 kHz usable frequency, and a primary continuous rating near 25 A with a finite V·μs headroom. These specs determine measurement accuracy, bandwidth, and V·μs margin that protect the core from saturation and define usable dynamic range for control loops.

Accurate current sensing in switching supplies depends on three interacting envelopes: core magnetics (inductance and saturation), burden and secondary resistance (sets signal amplitude and thermal loss), and frequency response (sets amplitude error and phase). The following sections break down core specs, operational limits, bench validation steps, integration notes, and replacement guidance for robust SMPS design and trouble‑shooting.

1 — Product overview & core specs (background)

Core electrical specs to list and explain

| Parameter | Typical / Notes |

|---|---|

| Turns ratio | 1 : 100 (primary single turn, secondary ~100 turns) |

| Primary rating | ~25 A continuous (use derating for ambient/temperature) |

| Secondary current (calc) | 25 A → 0.25 A secondary at 1:100 |

| Secondary DC resistance | ~2 Ω (burden and tolerance affect voltage) |

| Magnetizing inductance | ~18 mH (low‑frequency headroom) |

| Leakage inductance | low — design dependent; impacts high‑frequency rolloff |

| Max frequency | ~500 kHz usable (amplitude/phase degrade toward limit) |

| V·μs limit | finite V·μs — calculate margin per waveform to avoid saturation |

| Insulation / HI‑POT | specified in datasheet — verify for system isolation needs |

| Thermal / derating | recommend derate above steady ambient; check datasheet curves |

Each row ties directly to measurement fidelity: turns ratio sets gain and required burden resistor; magnetizing inductance sets low‑frequency droop and V·μs headroom; DC resistance and winding losses determine burden heating and offset. Use the table values as design anchors and verify per‑lot variation on incoming inspection.

Mechanical & package details

The transformer is a through‑hole PCB mount part with a small rectangular footprint and vertical lead exit. Recommended PCB keepouts include a minimal secondary loop area and clearance from high‑voltage switching nodes; lead spacing and standoff height determine routing and creepage. Mounting affects thermal dissipation and EMC: tight seating and short secondary traces preserve common‑mode immunity and reduce radiated emissions.

2 — Performance limits & safe operating area (data analysis)

Saturation, V·μs limits, and DC bias behavior

Point: DC offset or net flux from a nonzero average primary current will drive the core toward saturation. Evidence: finite magnetizing inductance (~18 mH) and specified V·μs headroom mean integrated voltage over a switching interval must remain below the core limit. Explanation: compute V·μs = Vprimary × ton; ensure the product divided by turns ratio and magnetics leaves margin. Derate for continuous DC or long transients.

Frequency response, bandwidth & accuracy vs. frequency

Point: amplitude droop at low frequency and roll‑off at high frequency both reduce accuracy. Evidence: usable bandwidth near 500 kHz implies measurable amplitude error and phase shift as frequency approaches that limit. Explanation: low‑frequency droop follows magnetizing impedance; high frequency behavior follows leakage/winding capacitance. Characterize amplitude error and phase at 100 kHz, 250 kHz and 500 kHz to quantify closed‑loop impact.

3 — Bench testing & validation procedures (method guide)

Basic electrical tests (what, how, expected ranges)

Start with turns ratio, secondary DC resistance, and inductance using an LCR meter: verify ~1:100 ratio, ~2 Ω DC R, and ~18 mH inductance. Perform insulation/HI‑POT to the datasheet value and visual inspection for discoloration. Required gear: LCR meter, calibrated current source or power supply, oscilloscope with differential probe, and hipot tester. Compare measured values to table tolerances to flag defects.

Calculation box: 25 A primary at 1:100 → 0.25 A secondary. With a 2 Ω burden this produces 0.25 A × 2 Ω = 0.5 V peak; for RMS or pulse calculations, scale by waveform shape and duty cycle. Use this to size burden resistor and ADC input ranges.

Dynamic tests: waveform, burden selection, and transient V·μs test

Set up a test where a controlled triangular or rectangular primary current waveform is injected and secondary voltage observed. Use a burden chosen to produce a safe, measurable voltage (for 25 A primary, burdens between 0.5–2 Ω yield 0.125–0.5 V secondary typical). Apply worst‑case ramp to measure V·μs headroom and record onset of saturation. Pass criteria example:

4 — Integration notes & typical applications (case study)

Use in SMPS feedback and protection loops

Primary uses include primary current feedback for regulation, peak‑current monitoring in flyback or forward stages, and overcurrent protection. Match bandwidth to switching frequency and ensure V·μs margin in topologies with large magnetizing volt‑microsecond products (flyback primaries). Typical connection: single‑turn primary conductor through core, secondary to burden resistor, then to sense amplifier or ADC input with appropriate filtering.

PCB layout, grounding, and noise-mitigation tips

Keep the secondary loop and burden resistor close and short to minimize loop area; use star grounding for the sense return and place the burden near the converter controller. Add small series ferrite or RC filtering on the secondary when necessary, and avoid routing secondary under noisy switching nodes to reduce induced error. Prevent stray DC by avoiding split primary paths or offset currents through adjacent copper.

5 — Troubleshooting & selecting replacements (action recommendations)

Common failure modes and diagnostic checklist

Symptoms include DC offset (partial saturation), increased noise (layout or partial short), or open secondary. Diagnose by measuring DC resistance versus expected ~2 Ω, verifying turns ratio, performing hipot, and inspecting for thermal discoloration. Thermal drift or sudden offset usually points to localized core heating or partial shorting in windings; replacement is safest if specs deviate significantly.

How to pick a replacement or alternative part

Match turns ratio and V·μs headroom first, then magnetizing inductance, DC resistance, frequency rating and mechanical footprint. For burden equivalence, recalc expected secondary current (Isec = Ipri / ratio) and ensure the replacement burden produces the same voltage into the sensing ADC or amplifier while remaining within power limits.

Summary

The FIS115NL functions as a 1:100 current sense transformer whose usable envelope is defined by magnetizing inductance (~18 mH), secondary DC R (~2 Ω), frequency limit (~500 kHz) and V·μs headroom for avoiding saturation. Practical takeaways: always verify V·μs margin for your SMPS topology, bench‑test turns ratio and dynamic accuracy at switching frequency, and follow PCB and grounding best practices to preserve measurement fidelity for regulation and protection.

Key summary

- Verify V·μs margin and magnetizing inductance before integrating a current sense transformer to prevent saturation under worst‑case ramps and DC offsets.

- Bench tests should include turns ratio, DC resistance, LCR inductance, and dynamic amplitude/phase checks at 100–500 kHz to confirm accuracy for the intended switching frequency.

- Layout matters: short secondary loops, star ground the sense return, and place burden resistor adjacent to the transformer to minimize noise and error.

Frequently asked questions

How to validate the FIS115NL turns ratio quickly?

Use a known low‑frequency AC source or LCR meter: excite the primary with a small AC voltage and measure secondary voltage, or inject a calibrated DC current pulse and measure steady‑state secondary current. The ratio should be about 1:100; large deviations indicate winding damage or incorrect part.

What burden resistor should be used with this current sense transformer?

Select the burden so the secondary voltage is within the amplifier/ADC range while keeping power dissipation acceptable. Example: at 25 A primary → 0.25 A secondary; a 2 Ω burden produces 0.5 V (peak) and 0.06 W dissipation—adjust burden to match sensing input and thermal budget.

How to test for V·μs induced saturation in this current sense transformer?

Apply a worst‑case ramp current waveform and monitor secondary voltage over the switching interval. Compute V·μs = Vprimary × ton and ensure the integrated flux does not exceed the transformer's V·μs headroom. Record the point of waveform distortion to determine safe operational margin and apply derating for continuous DC offsets.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP