-

- Contact Us

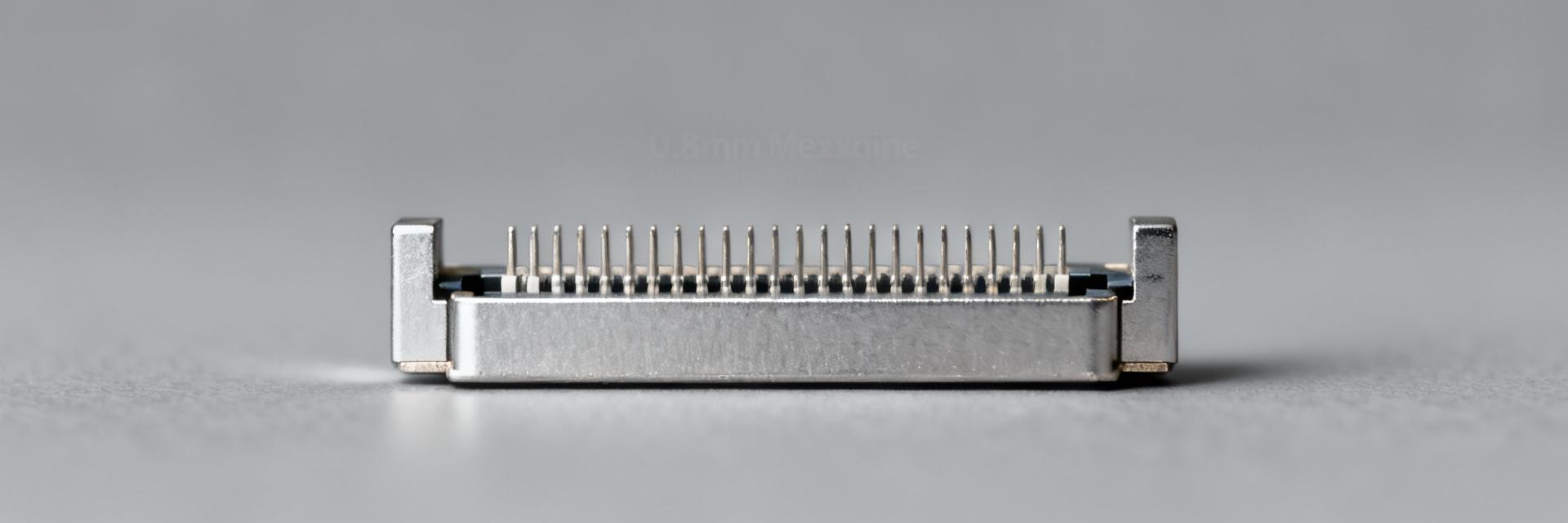

0.8mm Mezzanine Connector: Spec Breakdown & Data Report

Point: The 0.8mm mezzanine connector has emerged as a default choice for high‑density board‑to‑board mating in compact electronics. Evidence: aggregated distributor listings and procurement trend analyses show an expanded selection of 0.8mm solutions across portable, wearable, and IoT product families. Explanation: engineers favor the pitch for routing density while retaining manufacturability; this article delivers a clear spec breakdown and actionable data to evaluate candidates such as 61083-101402LF.

Point: This report focuses on measurable datasheet attributes and practical checks. Evidence: common datasheets cluster around mechanical stack heights, contact finishes, current ratings, and mating life. Explanation: by emphasizing testable specs and procurement considerations, the goal is to reduce ambiguity in part selection and speed qualification decisions for constrained board stacks.

Background & Design Context (background introduction)

1.1 Market & application snapshot

Point: The 0.8mm pitch is chosen to balance routing density with reliable assembly. Evidence: designers moving from wider pitches to 0.8mm report improved area efficiency in compact laptops, tablets, wearables, and embedded modules. Explanation: 0.8mm pitch supports single or dual row stacks for mixed signal and power distribution; takeaway — validate whether a mezzanine stack is preferable to flex or cable alternatives early in system partitioning.

1.2 Relevant specs and standards overview

Point: Typical datasheets enumerate a consistent set of specs engineers must verify. Evidence: standard datasheet categories include pitch, rows, positions, contact finish, current rating, mating cycles, and stack height. Explanation: refer to those specs as pass/fail criteria in your BOM; takeaway — list the critical specs you will accept and require them in procurement documents to avoid surprises.

Spec Breakdown: Mechanical & Physical Specs (data-analysis/specs deep-dive)

2.1 Pitch, rows, positions, and stack geometry

Point: Pitch, row count and positions determine routing feasibility and board alignment complexity. Evidence: 0.8 mm pitch points enable dense single‑ or dual‑row arrangements and influence the number of usable differential pairs. Explanation: interpret “positions” as populated contact count and check mating polarity/alignment features. Takeaway — verify part‑specific stack heights and mechanical alignment features; confirm the 0.8mm mezzanine connector footprint matches your keep‑out requirements.

2.2 Housing, contact finish, and mechanical tolerances

Point: Housing material, contact plating, and tolerances directly affect durability and signal behavior. Evidence: common finishes (gold over nickel or selective plating) with specified plating thickness and tolerance bands appear on datasheets labeled specs. Explanation: thicker gold improves mating cycles and corrosion resistance but raises cost; takeaway — confirm solder tail tolerances, board guides, and keep‑out dimensions before PCB release.

Electrical & Environmental Data Report (data-analysis / test-focused)

3.1 Electrical performance: current, impedance, and signal integrity

Point: Electrical specs constrain where a mezzanine connector can be used for power or high‑speed signals. Evidence: typical current ratings per contact and target contact resistance appear alongside SI notes like impedance control and crosstalk guidance. Explanation: for mixed signal designs, segregate power contacts and route differential pairs with controlled impedance. Takeaway — request high‑frequency insertion loss and crosstalk data for candidate parts if you plan >1 Gbps signals.

3.2 Environmental & reliability metrics

Point: Reliability metrics determine lifecycle suitability for the end product. Evidence: mating cycles, humidity/temperature ranges, shock and vibration levels are standard environmental entries on datasheets; use part numbers (for example 61083-101402LF) to look up detailed endurance data. Explanation: plan thermal cycling and vibration qualification in your program; takeaway — require supplier test reports or run mate/unmate cycle tests that mirror your product profile.

Use Cases, Compatibility & Comparative Notes (case-display)

4.1 Typical board-stack and mating configurations

Point: Multiple orientation and stack height options support distinct mechanical architectures. Evidence: common configurations include vertical, right‑angle, and offset stacks with varying retention schemes. Explanation: check mating counterpart pin counts, keyed protections, and retention mechanisms for assembly robustness. Takeaway — create a mechanical drawing showing stack tolerances and mating sequence for PCB fab and assembly vendors.

4.2 Comparing part families & picking by spec needs

Point: Choosing between high‑signal and mixed‑signal variants requires spec tradeoffs. Evidence: differences manifest in contact finish, row count, mating force, and mechanical life on datasheets. Explanation: use a quick checklist comparing electrical rating, mechanical life, mating force, and footprint constraints to narrow options. Takeaway — prioritize the parameter set that matches your dominant use case (power vs. high‑speed) and shortlist accordingly.

Design & Assembly Best Practices (method/guideline)

5.1 PCB footprint, routing, and mechanical support

Point: Footprint decisions drive assembly yield and connector reliability. Evidence: pad geometry, solder mask, alignment pin locations and keep‑outs are common recommendations in manufacturer drawings. Explanation: implement board‑to‑board alignment features and clearance zones to protect mating faces. Takeaway — define pad shapes and tolerance stacks in your PCB fab notes and include mechanical supports near high‑force connectors.

5.2 Reflow, inspection, and test recommendations

Point: Reflow profiles and inspection criteria ensure solder integrity and coplanarity. Evidence: surface‑mount mezzanine headers require controlled solder volumes and planarity specs to mate reliably. Explanation: inspect solder fillets and coplanarity post‑reflow and include mate/unmate functional tests in your assembly validation. Takeaway — add a coplanarity check and functional continuity test to your incoming inspection plan.

Procurement, Qualification & Action Checklist (action suggestions)

6.1 Sourcing, lead time & BOM notes

Point: Procurement clarity avoids wrong parts and lead‑time surprises. Evidence: packaging form (tape & reel vs. tray), alternate mapping and full part numbers are common procurement data. Explanation: specify the exact material and critical specs in the BOM; include 61083-101402LF or alternates with approved cross‑references. Takeaway — require packaging and lot traceability on purchase orders to prevent cross‑ships.

6.2 Qualification checklist for design sign-off

Point: A concise qualification list speeds production readiness. Evidence: pre‑production checks typically include datasheet verification, mate/unmate testing, thermal and vibration testing and supplier change notifications. Explanation: cross‑reference each test to your product's environmental profile. Takeaway — deploy a go/no‑go checklist that covers mechanical, electrical, and environmental pass criteria before sign‑off.

Summary (conclusion & next steps)

- Verify mechanical stack height, pad geometry and alignment features against your PCB design before finalizing the BOM for a 0.8mm mezzanine connector.

- Confirm electrical specs (current rating, contact resistance, SI data) and request high‑frequency test data for high‑speed channels.

- Require mating cycle and environmental test evidence, and include mate/unmate and coplanarity checks in incoming inspection.

FAQ

What are the essential specs to check for a 0.8mm mezzanine connector?

Check pitch and positions, stack height, contact finish/plating thickness, current rating, contact resistance, and mating cycles. Require footprint drawings and tolerance tables to ensure the part will mate reliably in production and meet your electrical and mechanical needs.

How should I validate signal integrity for mezzanine connector usage?

Request insertion loss, return loss, and crosstalk measurements at your target data rates or supply representative test boards for supplier measurement. If unavailable, perform your own S‑parameter measurements on prototype stacks and route differential pairs with controlled impedance.

What procurement details reduce cross‑ship risk for connector parts?

Specify full part numbers, acceptable alternates, packaging form, and plating finish in the BOM. Require lot traceability and confirm lead times; include acceptance criteria for incoming inspection to ensure the received parts match required specs before assembly.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- Tamura L34S1T2D15 Datasheet Breakdown: Key Specs & Limits

- PAL6055.700HLT Datasheet: Complete Technical Report

- FDP027N08B MOSFET Datasheet Deep-Dive: Key Specs & Test Data

- LT1074IT7: Complete Specs & Key Parameters Breakdown

- How to Verify G88MP061028 Datasheet and Specs - Checklist

- NFAQ0860L36T Datasheet: Measured IPM Performance Report

- 90T03P MOSFET: Complete Specs, Pinout & Ratings Digest

- 3386F-1-101LF Datasheet & Specs — Pinout, Ratings, Sources

-

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4050NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP

MM74HC4049NSanyo Semiconductor/onsemiIC BUFFER NON-INVERT 6V 16DIP -

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NSanyo Semiconductor/onsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NSanyo Semiconductor/onsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NSanyo Semiconductor/onsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP

MM74HC374NSanyo Semiconductor/onsemiIC FF D-TYPE SNGL 8BIT 20DIP -

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP

MM74HC373NSanyo Semiconductor/onsemiIC D-TYPE TRANSP SGL 8:8 20DIP -

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Linear Technology (Analog Devices, Inc.)IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP

MM74HC259NSanyo Semiconductor/onsemiIC LATCH ADDRESS 8BIT 16-DIP -

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP

MM74HC251NSanyo Semiconductor/onsemiIC MULTIPLEXER 1 X 8:1 16DIP